Our goal is simple, to manufacture quality parts on time for our customers.

Our success is achieved through implementation and enforcement of an effective ISO-9001:2015 Quality Management System which includes a strong internal audit and corrective action system, planning of product realization and monitoring and measurement of product.

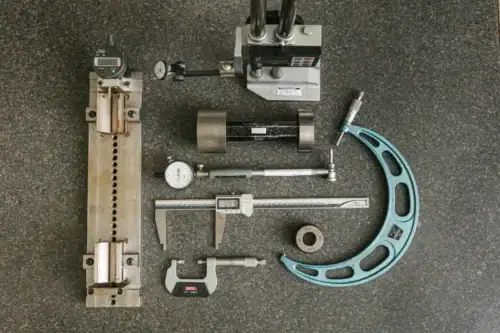

Our Production Teams measure and document product characteristics in process as required by our manufacturing instructions and quality system. Typical monitoring and measurement devices include, but are not limited to, the following:

- Digital, Dial and Vernier Calipers with ranges up to 40”

- Digital and Vernier Micrometers, 0-12”

- Digital and Dial Bore Gages

- Digital and Dial Indicators

- Plug and Ring Thread Gages

- Go/No-Go Gages

- Customized Plug Gages

- Automated Overall Length (OAL) Gages

- Height Stands and Dial Test Indicators

- Multiple Surface Plates

Our Calibration Lab uses the following equipment to calibrate the monitoring and measurement devices used by our Production Team to verify product compliance:

- Zeiss Spectrum 7/10/6 RDS Coordinate Measuring Machine. Calibration is traceable to NIST (National Institute of Standards and Technology) and has an accuracy of +/-.0002”.

- MIC TRAC GAGEMAKER Universal Measuring Machine model 2024; Calibration is traceable to NIST and has an accuracy of +/-.00005”.

- Links Gage Block set (81 pieces), Grade 2; Calibration is traceable to NIST.

- Gagepack Calibration Software used to maintain an effective calibration and gage control system.